Men’s rings made from whiskey barrels have got to be some of the coolest wedding bands we get to make! It’s the ultimate in upcycling, and we love how each one is different from the next.

The history behind whiskey barrels is fascinating. To learn more about how whiskey barrel wood gets turned into men’s wedding bands, read on! To skip ahead, check out our product page for the ring we appropriately named The Whiskey Barrel or check out our entire Whiskey Barrel Collection.

A Little Whiskey Barrel Background

The traditional whiskey barrel is made from American white oak harvested from trees grown in the middle to eastern parts of the U.S. and eastern Canada. Strips of wood are carefully bent and bound together with steel hoops. Then two round ends are attached, and the result is an airtight and waterproof 52-gallon container. Barrel makers, also known as “Coopers,” use a very specific (and a little bit secret) process in creating these wooden wonders.

- Drying. A whiskey barrel begins its journey as raw planks of wood that have to be stacked and dried for up to several months. How long the wood needs to dry depends on the final product that it’ll be used in making.

- Cutting. Next, 31-33 boards are strategically cut in specific patterns to create the planks (or staves) that make the sides of the barrel as well as the round tops and bottoms.

- Assembling (a.k.a. “raising”). The staves are arranged into a narrow-wide-narrow-wide pattern. This ensures that the pressure on the barrel will be evenly distributed among all the pieces when it is finished. Otherwise, the barrel will leak. Nobody wants that!

- Steaming. If you try to bend dry wood, it splinters and breaks. So hot steam is blown through the staves while they’re hanging from a steel ring. Once they’ve enjoyed a little spa treatment and are super relaxed, a second ring is slipped onto the other end. Now, it starts to look like a barrel!

- Heating. This is the super-secret part we mentioned earlier. Since the process of making whiskey is all about the flavor extracted from wood as it ages, the insides of the barrels have to be toasted to bring all that flavor to the surface

This extreme heat makes the natural sugars and other substances in the wood rise to the surface, which is great for whiskey makers for two reasons:

- The barrels expand and become waterproof.

- The sugar caramelizes on the inside of the barrel. Later, when the whiskey is added, that sugar will get absorbed by the liquid to make it taste just right.

Next, the outsides of the barrel are charred. How much the wood is burnt determines a lot about the final flavor of the bourbon or whiskey inside. Each distiller has different requirements…and more than a few secrets about how long and how hot they do it.

After that, the rest of the steel bands are added and the barrels get tested before being sent out. How they get turned into wood rings later in life by folks like us is pretty fascinating too!

How Men’s Rings Get Made From Whiskey Barrels

- We cut one of the charred barrel staves down to size. Rings aren’t that big, really. So it only takes a little bit of wood.

- We drill a hole roughly the size of the ring, right through the little square section of oak.

- We make it into a rough circle by trimming off the excess and sanding the corners smooth using a lathe.

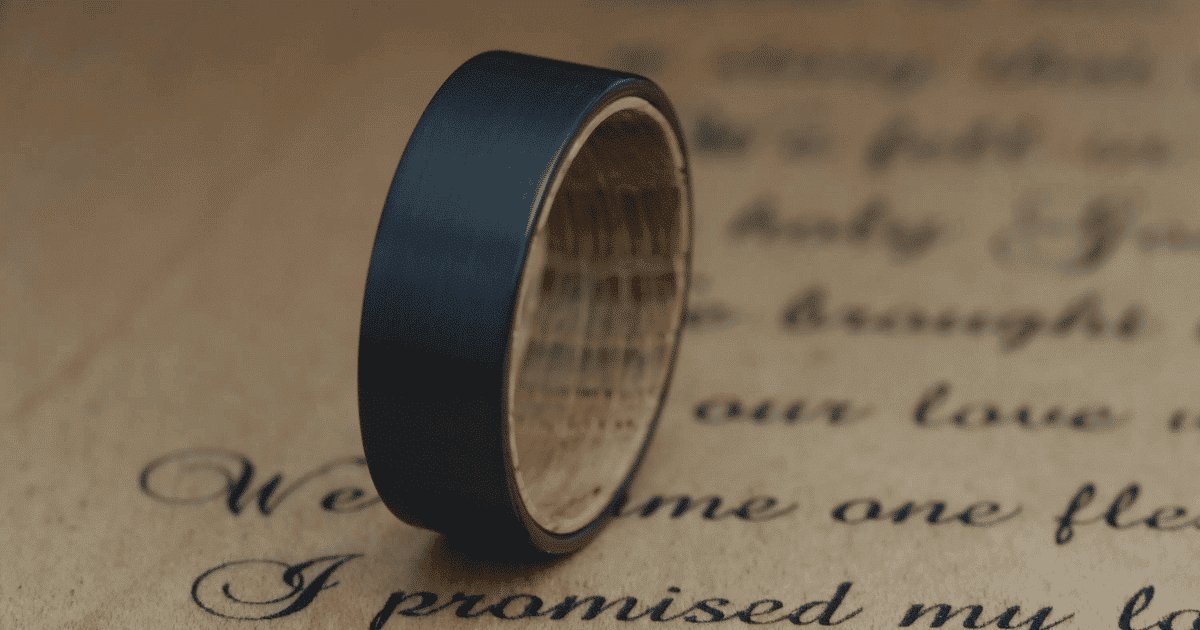

- We drill holes in metal! In the case of The Whiskey Barrel band, we use black tungsten. (However, barrel wood pairs well with virtually any kind of metal. We just think the contrast of the rich deep black against the grain of the oak is extremely cool.) Using extreme precision, we drill out a hole in the tungsten just slightly larger than the outer thickness of the barrel band.

- We glue the two parts together. Once the metal band is carefully trimmed to size, the wood ring is coated with epoxy and slid into place inside the tungsten band. At this point, the wooden ring is wider than the metal one. But that gets fixed in the final step.

- We sand, polish, and ship. Saying it like that makes it sound simple, but we really spend a lot of time at this point adding layers of protective coating to the wood. Then we sand and polish everything over and over and over until your ring is perfectly smooth and unbelievably beautiful. Only then does it get boxed up and sent out.

What Buying a Whiskey Barrel Ring from Gentlemen’s Bands Means

Every ring we make comes with a lifetime warranty. That means if anything ever happens to your ring, we’ll make it right. Period.

All of our rings include a complimentary silicone activity band. We totally understand that your new ring is something you want to protect when you decide to work hard or play rough. So we give you a nice activity band to wear when you don’t want to risk anything going wrong.

Shipping is always free. If you order within the domestic U.S., the shipping is on us! Plus, we’ll always send you a tracking number so you’ll know exactly where it is and when it arrives.

So if you’re trying to find the perfect men’s ring made from a whiskey barrel, look no further!

➡️ Shop Now

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.